ATEX

Equipment for potentially explosive dust environments

What is ATEX ?

ATEX is an abbreviation for the french term “ATmosphères EXplosible” and refers to atmospheres that are potentially explosive

Explosions can cause loss of life and serious injuries as well as significant damage. Preventing releases of dangerous substances which can create explosive atmospheres and preventing sources of ignition are two widely used ways of reducing the risk. Using the correct equipment can help greatly with this.

Pre-conditions for a dust explosion

1. Ignition Source

To ignite the dust, energy is needed. It can come from a small source of static electricity, a larger energy source such as an open flame, electrical faults, or heating if enough dust accumulates on awarm surface.

2. Oxygen

Combustion requires oxygen, normally the oxygen content in air is sufficient to create an explosive environment.

5. Containment

If the explosion occurs in a containment, this can result in a rapid increase in pressure.

3. Combustible Material

The size of the particles is of great importance, smaller particles are more flammable and easier to disperse in the air. The concentration of dust is also of great importance and must be within a given range for an explosion to occur.

4. Mix

The dust must be airborne. Even dust that is not normally airborne can become so in connection with another explosion or external influence.

Risk Assessment

The consequences of a dust explosion can be devastating in terms of both material and personal. In the OSH directive 1999/92EU, the employer is ultimately responsible for ensuring that the production facility is built safely, that the staff is trained and must, in accordance with the mandatory regulations, have drawn up a so-called explosion protection document. It shall contain risk analyzes, classification plans, a list of flammable liquids, gases and dust as well as routines for safe handling in the event of an explosive atmosphere.

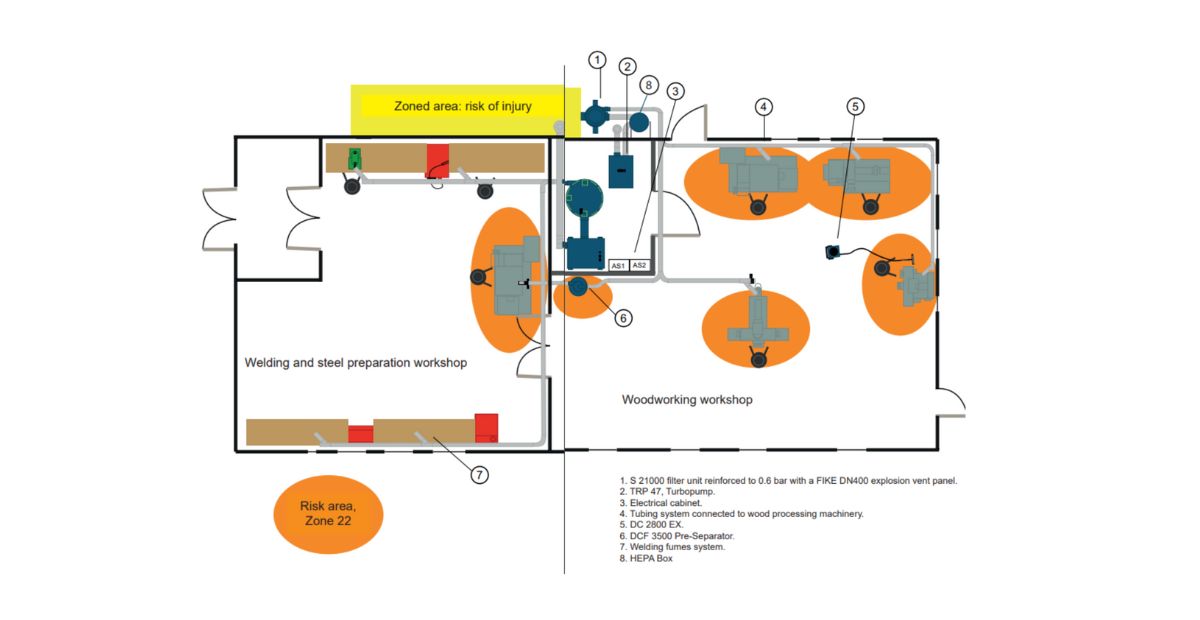

Depending on the frequency and duration of an explosive atmosphere, the risk area is divided into zones:

OUR ATEX COMPLIANT MACHINES & SYSTEMS

- AT A GLANCE

EX LINE MOBILE EXTRACTORS

DC1800 H EX

DC 2800 H EX

DC TROMB TURBO EX

DC 5800 H TURBO EX

EX STATIONERY EQUIPMENT

The DC 11-Module XL is a complete central unit for source extraction and industrial cleaning.

The unit can manage just about every kind of dust and chip you can imagine, even coolants and emulsions when equipped with a pre-separator.

The XL-model can handle more extraction points at a time than the standard model.

The EX Line is specially designed to fulfil the requirements of the Atex Zone 22 directive 2014/34 EU Zone 22 is an area where an explosive environment, created by combustible airborne substances, does not occur in normal operation or occurs short term. These machines are equipped with steel containers, earth bonded parts and antistatic accessories